Eurorack Case

Case Design

Market research

The previous year’s speaker building emboldened me to spend even more money and tackle a new project. This was probably c. 2018, when eurorack was on the upswing in terms of its mainstream popularity. I had cracked the seal with a Bass Station ii and MS-20 mini earlier in the year and was looking to dip my toes into the modular waters as a way of extending my functionality.

I was shocked to see how expensive eurorack cases were. There’s a lot of analog fetishism around fit and finish in this world, especially amongst boomers who, having finally amassed enough wealth to indulge themselves in the gear lust, are now keen to build shrines to their fading youth.

Once more, I figured I could build something myself.

I’m sure I could do that

The most cost-effective solution at the time seemed to be the TipTop Mantis case. At $300, it packed 2 104HP rows, with ample power to fill it. However, I wasn’t sure that 208HP would be enough… and I felt like building something again, so I figured I could save some money doing it on my own. Notice a theme?

More Woodworking

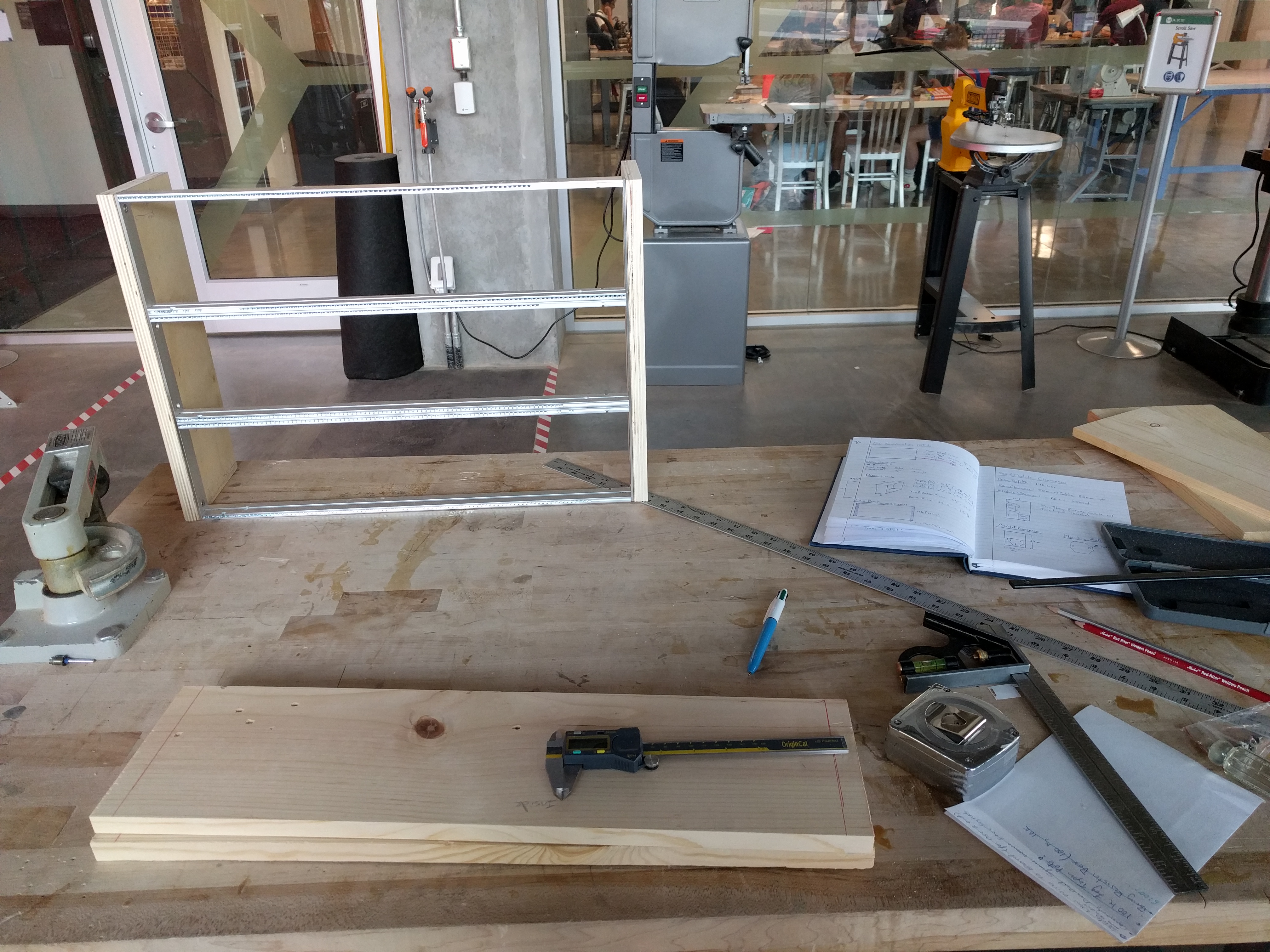

By this time I learned that the university had a maker space for wood and metal working. I figured I could cobble something together from plywood scraps:

Not bad for an afternoon.

Components

Sourcing rack rail is harder than it should be, and expensive. Digikey had the best prices for the TS209 vector rail (only $10/ea back in 2018), but it was still a bit of a head scratcher to figure out what kind of rail to get, and from where. Also, why was it easy to get 104HP rail, but only 84HP threaded insert! I wish I would have bought extra and filled in the gaps, but didn’t have the tools (or money, patience) for cutting the inserts and figured the floating nuts would be a decent compromise. They suck.

Erthenvar (now-defunct) came in handy for rail sides.

Power Supplies

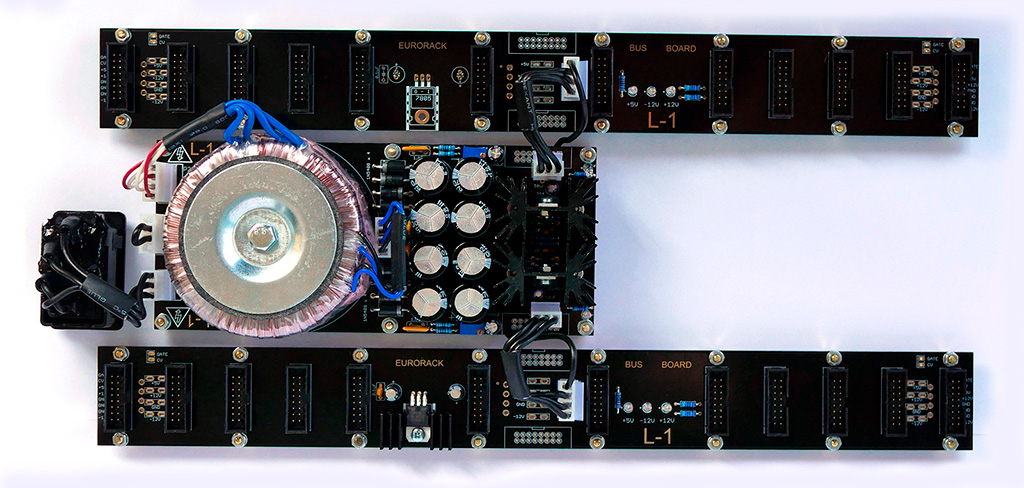

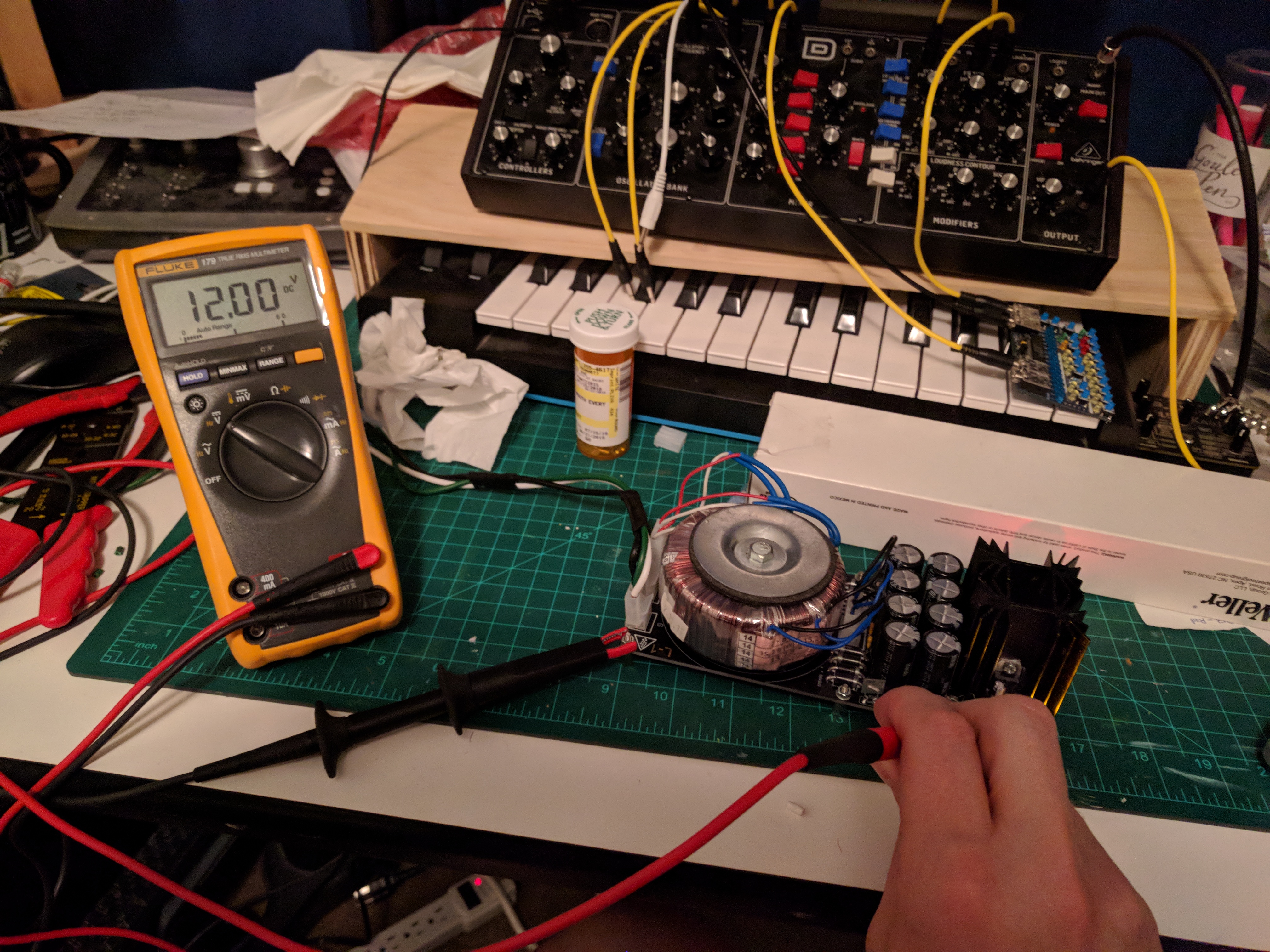

In the spirit of over-engineering everything, I opted to go with a linear power supply. I found L-1 recommended on MW and decided it would be fun to build on my own from a kit. On receipt, I was pretty disappointed with the no-name components, undersized thermal fuse and heatsinks, and the fact that the power distribution boards had a missing trace. I needed to jumper some of the grounds, buy a bunch of replacement caps, thicker guage wire, and better heatsinks to increase chances for success. In the end everything powered on fine and worked, but I’d have been better off buying a Condor power supply or something.

I also opted to replace the IEC receptacle with something a bit more skookum. Whatever the L1 shipped with felt pretty cheap and I wasn’t about to fry myself (or, god forbid, the modular).

In the end, the already pricey linear supply cost me an additional ~$80 in additional components to have something that could withstand the rigors of sitting on my desk.

The case is now 2/3rds full, and fast on its way to becomming the most underwhelming $4k Moog Grandmother clone.